Tag Archives: hyperpool shaker

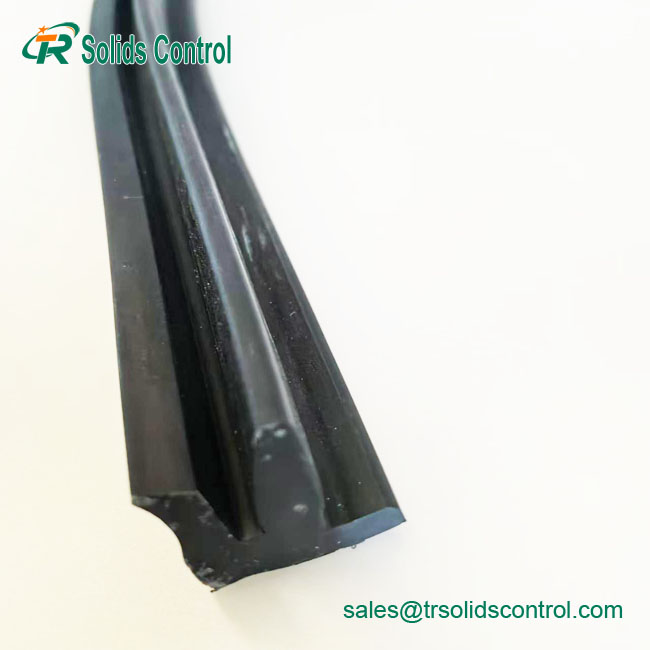

16848-11 Buldhead Protector Double for HyperPool Shakers

The 16848-11 Buldhead Protector Double is engineered with advanced materials that offer superior protection against impacts and abrasions. It is design features double-layered construction. The double-layered construction significantly increases its durability and effectiveness in safeguarding the head.

The role in maintainingthe performance of hyperpool shakers is the 16848-11 Buldhead Protector Double. how it enhances the functionality of hyperpool shakers.

Understanding Hyperpool Shakers

Hyperpool shakers are vital in the drilling process. It is used to separate drilling fluids from cuttings. They ensure that the drilling operation remains efficient by recycling the drilling fluid. It is essential for maintaining pressure and cooling the drill bit. Given the harsh conditions under which these machines operate. It is crucial to equip them with high-quality 16848-11 Buldhead Protector.

The Role of the 16848-11 Buldhead Protector Double

The 16848-11 Buldhead Protector Double is specifically designed to provide enhanced protection for hyperpool shakers. This component acts as a barrier against the abrasive materials and harsh chemicals that are often present in drilling environments. The Buldhead Protector Double helps to prevent wear and tear, ultimately extending the lifespan of the equipment.

Key Features of the 16848-11 Buldhead Protector

1. Durability:

Constructed from high-quality materials, the 16848-11 Buldhead Protector Double is built to withstand extreme conditions. It is robust design ensures that it can handle the abrasive nature of drilling fluids and cuttings.

2. Easy Installation:

The design of the Buldhead Protector Double allows for straightforward installation on hyperpool shakers. This ease of installation minimizes downtime, enabling operators to quickly replace worn components and maintain operational efficiency.

3. Compatibility:

The 16848-11 Buldhead Protector Double is engineered to be compatible with various models of hyperpool shakers. This versatility makes it a preferred choice for many operators looking to enhance their equipment without the need for extensive modifications.

4. Cost-Effectiveness:

Investing in the Buldhead Protector Double can lead to significant cost savings in the long run. By reducing the frequency of repairs and replacements for the shaker. Operators can lower their maintenance costs and improve overall productivity.

The integration of the 16848-11 Buldhead Protector into hyperpool shakers protects the machinery. By ensuring that the shaker operates at optimal performance levels, operators can achieve better separation of drilling fluids and cuttings. This improved efficiency translates to reduced waste and lower operational costs, making it a win-win for drilling operations.

The 16848-11 Buldhead Protector Double is an indispensable component for hyperpool shakers in the oil and gas industry. The importance of high-quality protective components like the Buldhead Protector Double will only grow. hyperpool shakers can meet the demands of modern drilling operations.

Contact us today to learn more about Side Support Rubber and shaker screens, how TR can support your solids control needs with innovative solutions.TR is a professional manufacturer for producing Solids Control System and Solids Control Equipment.If you need mud shale shaker, We will provide the high quality drilling shale shaker and best service. Your best Mud Recycling System start from TR solids control.

16848-11 Buldhead Protector Double

The 16848-11 Buldhead Protector Double is engineered with advanced materials that offer superior protection against impacts and abrasions. It is design features double-layered construction. The double-layered construction significantly increases its durability and effectiveness in safeguarding the head.

The role in maintainingthe performance of hyperpool shakers is the 16848-11 Buldhead Protector Double. how it enhances the functionality of hyperpool shakers.

Understanding Hyperpool Shakers

Hyperpool shakers are vital in the drilling process. It is used to separate drilling fluids from cuttings. They ensure that the drilling operation remains efficient by recycling the drilling fluid. It is essential for maintaining pressure and cooling the drill bit. Given the harsh conditions under which these machines operate. It is crucial to equip them with high-quality 16848-11 Buldhead Protector.

The Role of the 16848-11 Buldhead Protector Double

The 16848-11 Buldhead Protector Double is specifically designed to provide enhanced protection for hyperpool shakers. This component acts as a barrier against the abrasive materials and harsh chemicals that are often present in drilling environments. The Buldhead Protector Double helps to prevent wear and tear, ultimately extending the lifespan of the equipment.

Key Features of the 16848-11 Buldhead Protector

1. Durability:

Constructed from high-quality materials, the 16848-11 Buldhead Protector Double is built to withstand extreme conditions. It is robust design ensures that it can handle the abrasive nature of drilling fluids and cuttings.

2. Easy Installation:

The design of the Buldhead Protector Double allows for straightforward installation on hyperpool shakers. This ease of installation minimizes downtime, enabling operators to quickly replace worn components and maintain operational efficiency.

3. Compatibility:

The 16848-11 Buldhead Protector Double is engineered to be compatible with various models of hyperpool shakers. This versatility makes it a preferred choice for many operators looking to enhance their equipment without the need for extensive modifications.

4. Cost-Effectiveness:

Investing in the Buldhead Protector Double can lead to significant cost savings in the long run. By reducing the frequency of repairs and replacements for the shaker. Operators can lower their maintenance costs and improve overall productivity.

The integration of the 16848-11 Buldhead Protector into hyperpool shakers protects the machinery. By ensuring that the shaker operates at optimal performance levels, operators can achieve better separation of drilling fluids and cuttings. This improved efficiency translates to reduced waste and lower operational costs, making it a win-win for drilling operations.

The 16848-11 Buldhead Protector Double is an indispensable component for hyperpool shakers in the oil and gas industry. The importance of high-quality protective components like the Buldhead Protector Double will only grow. hyperpool shakers can meet the demands of modern drilling operations.

Contact us today to learn more about Side Support Rubber and shaker screens, how TR can support your solids control needs with innovative solutions.TR is a professional manufacturer for producing Solids Control System and Solids Control Equipment.If you need mud shale shaker, We will provide the high quality drilling shale shaker and best service. Your best Mud Recycling System start from TR solids control.

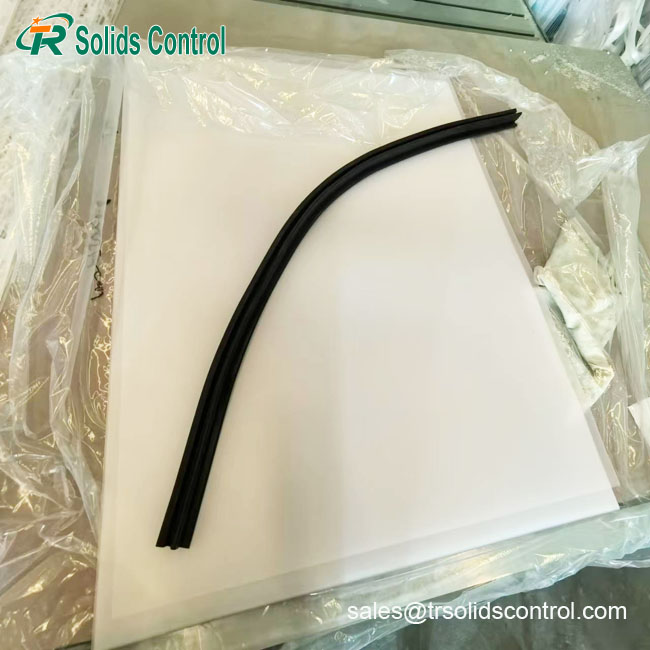

16848-01-001 Side Support Rubber

The importance of the 16848-01-001 side support rubber for hyperpool shaker.This part plays a vital role in ensuring the stability and functionality of various machines, particularly in applications where support and cushioning are necessary.

Understanding the Role of Side Support Rubber

The 16848-01-001 side support rubber is designed to provide essential support to machinery, helping to absorb shocks and vibrations that can occur during operation. This rubber component is typically used in conjunction with other parts to create a stable environment for machinery to function optimally.Its primary purpose is to prevent excessive movement and wear, which can lead to mechanical failure or reduced efficiency.

Key Features of 16848-01-001 Side Support Rubber

- Durability: One of the standout features of the 16848-01-001 side support rubber is its durability. Made from high-quality rubber materials, it is designed to withstand harsh conditions, including extreme temperatures and exposure to various chemicals. This resilience ensures that the component maintains its integrity over time, reducing the need for frequent replacements.

- Shock Absorption: The rubber’s inherent properties allow it to absorb shocks effectively. This is particularly important in applications where machinery experiences constant movement or vibration. By dampening these forces, the side support rubber helps to protect sensitive components from damage, thereby extending the lifespan of the equipment.

- Versatility: The 16848-01-001 side support rubber is versatile and can be used in a wide range of applications. Whether in automotive, industrial, or consumer products, this component can be found in various machines, providing essential support and stability.

- Easy Installation: Another advantage of the 16848-01-001 side support rubber is its ease of installation. Designed to fit seamlessly into existing machinery setups, it can be quickly and efficiently replaced when necessary, minimizing downtime and maintenance costs.

Applications of 16848-01-001 Side Support Rubber

The applications of the 16848-01-001 side support rubber are vast. In the automotive industry, it is often used in suspension systems to provide stability and comfort during driving. In industrial machinery, it can be found in conveyor systems, where it helps to support and stabilize moving parts. Additionally, in consumer products, such as appliances, this rubber component ensures that devices operate smoothly and quietly.

The 16848-01-001 side support rubber is an indispensable component in various machinery and equipment. Its durability, shock absorption capabilities, versatility, and ease of installation make it a preferred choice for manufacturers and maintenance professionals alike. As industries continue to evolve and demand more from their machinery, components like the 16848-01-001 side support rubber will remain crucial in ensuring operational efficiency and longevity. Investing in high-quality side support rubber not only enhances the performance of equipment but also contributes to overall safety and reliability in various applications.

Contact us today to learn more about Side Support Rubber and shaker screens, how TR can support your solids control needs with innovative solutions.

Thanks for visiting our website. Please feel free to leave a message if you any questions.

Contact Us:TR Solids Control

Sales office:No.10 West of North 2nd Ring Road Xi’an City, Shaanxi Province.

Manufacture: No.2 Goods yard road Xianyang City, Shaanxi Province.

Tel:+86-29-86332919

Call:+86-18509252400

E-mail:sales@trsolidscontrol.com